Screw Briquette Machine

- Power: 2.2*2kw

- Capacity: 150-350kg/h

- Application: Screw briquette machine can process biomass material like sawdust, rice husk, wooden material, etc, suitable for charcoal making factories or small scale briquette making industries.

It use biomass raw material such as wood chips, rice husk, peanut shell, farmland waste, etc. Also be named biomass briquette mahine.

GCBC Series Charcoal Briquette Machine

GCBC series charcoal briquetting machine is screw type biomass briquette machine. The screw design of this briquette machine makes it possible to produce processed into a cylindrical or hexagonal hollow center, it is easy to process and complete combustion and easily stacked for storage and transport.

GCBC-I Charcoal Briquette Machine GCBC-II Charcoal Briquette Machine

| Model | GCBC- I | GCBC-II |

|---|---|---|

| Output capacity kg/h | 180-210 | 300-350 |

| Motor Power (kw) | 15 | 18.5 |

| Electric heater (kw) | 2.2*2kw | 2.2*2kw |

| Size of briquettes | Dia.50mm*L.480mm | Dia.60mm*L.500mm |

| Size of inside hole | Dia.16mm | Dia.16mm |

| Density of briquettes | 1.3 g/cm3 | 1.3 g/cm3 |

| Weight(kg) | 700kg | 1000kg |

| Packing Weight(kg) | 800kg | 1100kg |

| Overall dimension(mm) | 2700*600*1600 mm | 2000*600*1700 mm |

| Life of the inner former | 1-2years | 1-2year |

video of Screw Briquette Machine

GCBA Series Screw Briquette Machine

GCBA series screw briquette machine is in screw type, it produces hollow hexagonal or quadrangular cylinder with a 15-20mm hole through the body.The briquettes produced by a screw press is easily handled and stacked, and they have some advantages over those produced using the ram and die press, such as better efficient combustion due to the central hole and carbonized outer layer.

GCBA series screw briquette machine have automatic temperature control system, it is designed to produce high density wood or biomass briquette as biofuel.

GCBA-I Screw(Charcoal) Briquette Machine GCBA-II Screw(Charcoal) Briquette Machine

| Model | GCBA-I | GCBA-II |

|---|---|---|

| Output capacity kg/h | 180-210 | 280~350 kg/h |

| Motor Power (kw) | 18.5kw | 22 kW |

| Electric heater (kw) | 5kw | 5 kw |

| Size of briquettes | Dia.50mm | Dia.60mm |

| Size of inside hole | Dia.16mm | Dia.18mm |

| Density of briquettes | 1.3 g/cm3 | 1.3 g/cm3 |

| Weight(kg) | 560kg | 780 kg |

| Warranty | 12 Months | 12 Months |

| Overall dimension(mm) | 1600*1000*1000 | 1500*1200*1600 mm |

|

|

|

|

| bagasse briquettes | maize straw briquettes |

Charcoal Briquette Plant

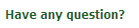

Flowchart of Swadust Charcoal Briquette Line

1. Biomass raw materials (sawdust, wood, stalk, straw or other crop and forestry waste) ↓

2. Crushing (crusher or hammer mill) ↓

3. Conveyor ↓

4. Drying (drying machine) ↓

5. Briquetting (biomass briquette machine) ↓

6. Semi-finished charcoal briquettes (their surface is charred, and they are also called wood briquettes or biomass briquettes) ↓

7. Charring (carbonization furnace) ↓

8. Finished charcoal briquettes ↓

Customer Case

Biomass Briquette Plant for Egpyt Customer

Biomass Briquette Plant for Korea Customers

Product List

- Hydraulic Briquette Press

- Industrial Briquette Maker

- Screw Briquette Machine

- Biomass Briquetting Plant

Project

News

Celebration for 14 Anniversary Day of Our Company’ Founding

Sep 10, 2018

Sep 10, 2018

September 7, 2018 is a memorable day for all the staff of our company, because the day is the big of 14 annive...

ABC Machinery Attend The 122th Autumn Canton Fair

Oct 18, 2017

Oct 18, 2017

The 122th Autumn Canton Fair held in Guangzhou, China during October 15 -19, 2017....

Copyright Notice

May 19, 2017

May 19, 2017

All the content o this site such as logo, photograph, product information, project information and company new...